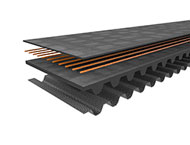

The Poly Chain® GT™ Carbon™ Belt construction utilises a polyurethane body combined with carbon fiber tensile cords for increased capacity and performance.

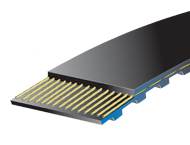

Poly Chain® HTD® allows the use of existing 14M HTD sprockets while increasing the capacity of the drive.

These short length versions are suitable for all industrial markets requiring a short center distance but high-density power.

Poly Chain® GT™ Carbon™ – 5MGT belts are ideally suited for use in machine tool, roller chain, small conveyors and compact drives where space is a problem.

Poly Chain® Carbon™ Volt™ belts deliver unmatched antistatic performance and meets ISO 9563 standards from start to finish.

Gates classical synchronous PowerGrip® belt oflers a maintenance free and economical alternative to conventional drives like chains and gears.

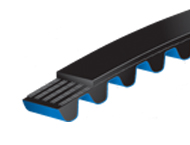

Introducing PowerGrip™ GT4™, a newly designed ethylene elastomer high-torque synchronous belt.

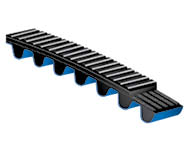

Twin Power® belts have teeth on both sides for synchronisation from both driving surfaces.

PowerGrip® HTD® belts have a larger, more robust tooth profile for increased capacity, as compared to timing belts.

Twin Power® belts have teeth on both Sides for synchronisation from both driving surfaces.

Gates Twin Power® GT® 2 belt has at least twice the power rating of Gates Twin Power® HTD® belts.

Available in 8M and 14M pitches, this belt is the optimum choice for high-performance, high-torque conditions and quiet operation.

The PowerGrip® TruMotion belts are available in all of Gates light-duty synchronous pitches.

Cost effective, low maintenance drive alternatives that are well suited for linear movement, positioning and conveying applications.

Endless urethane construction provides higher strength as compared to welded urethane belts, making them well-suited for use in power transmission and high-performance positioning applications.

Cotton Cleaner belts are specifically designed for use on cotton gin and inclined cleaner machines.