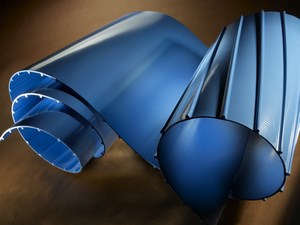

Food Grade Conveyor Belting

PosiClean® Food Grade Belting

PosiClean® is a line of easy to clean urethane food processing belting designed with sealed tension members and drive teeth across the full belt width. The belt can be cleaned-in-place with resulting savings in water, labor and waste water disposal when compared to plastic modular belting. The tension members eliminate belt stretch, a common cause of belt failure in long length applications.

Product Features

- Direct replacement of most 1” and 2” plastic modular belting.

- Smooth surface allows cleaning to microbiological level and clean-in-place process

- Sealed edges and tension members prevent ingress of microbes

- Kevlar tension members provide high strength, low stretch

- Tough polyurethane construction

- Water and chemical resistant

- Meets FDA material requirements for wet food contact

|

|

- Welded endless or splicing options available

- Stainless steel lacing

- PosiLace™

- Plastic rivets

- USDA accepted for meat, poultry and dairy processing equipment

- Runs on most plastic modular pulleys

- Optional sidewalls and flights available

|

|

PC10

- Direct drop-in replacement for most 1” plastic modular belting.

-180° wrap for most 6, 8, 10, 12 and 20 tooth modular pulleys.

- 2” minimum pulley diameter

|

|

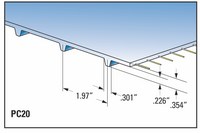

PC20

- Direct drop-in replacement for most 2” plastic modular belt

-180° wrap around most 8, 10, and 12 tooth modular pulleys

- 4” minimum pulley diameter

- Fits monolithic urethane belt pulleys as well

- Can be used with the PosiLace™ pin fastening system

- Available in two cord per inch for light to medium applications and four cord per inch for hi-torque applications

- Cold temperature urethane available

|

Application Characteristics

- Replacement for plastic modular belt and fabric belt

- Quieter operation

- Easier cleaning

- No hinges or pins to break and contaminate product

- Designed for clean-in-place protocol

- Less labor and cleaning water than plastic modular belt

PosiClean® Sprockets

Split Sprockets

- Split for easier/more cost efficient drive conversions

-Simply cut off existing sprockets

-Design takes 40mm & 1.5” square shafts

Solid Sprockets more suited to new applications for reduced cost

|

|

Fastening Options

For Field Welding

Mectrol has developed the “split tooth” method

- 2.4 to 3.8 times the weld surface area (depending �on the pitch) when compared to welding just the base belt

- Positions weld away from belt flex area

| PosiLace™

This pin fastened method meets low to medium load requirements without welding to achieve the maximum allowable tension.

Belt ends are prepared at the factory and the belt is joined by a single pin inserted after the belt is placed in position on the equipment.

This “living” fastening solution allows for removal and replacement of the belt as often as desired – without ever having to weld.

|

|

Other Mechanical Fasteners

From wire hooks to metal staples, standard conveyor fasteners are available when contamination is not an issue.

To discuss a food grade belting solution that is right for you, contact us at gatestech@gates.com.