Hydraulic Hose Laylines

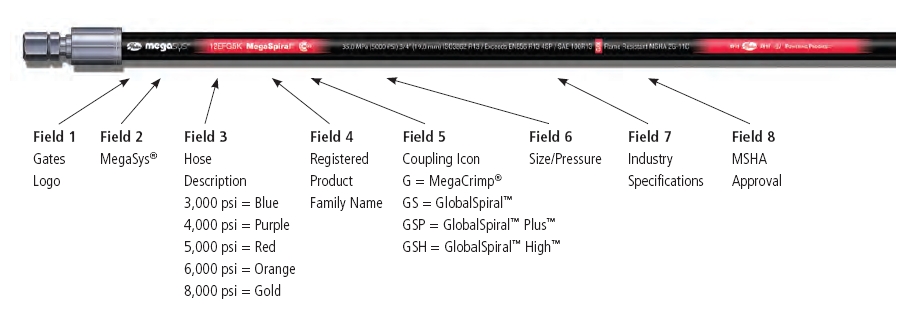

MegaSys

® hoses have colour coded laylines and constant pressure ratings through all sizes, making the hoses easier to identify in stock and in service while reducing inventory requirements. The layline indicates hose trade name, size and pressure; SAE, EN or DIN standard; and US MSHA flame resistance compliance.

These laylines are used exclusively on MegaSys® hoses. Distinctive design and pressure colour coding makes MegaSys® hoses easy to identify in stock or in service. See the layline example below.

|

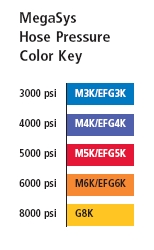

MegaSys® Hydraulic Hose Pressure Colour Key

Gates have established a new and easy to use hierarchy for the MegaSys® hydraulic hose range when it comes to pressure ratings and identification. The MegaSys® hoses now have constant working pressures with a matching colour system built into the hose layline. Beginning with the cooler colours, blue for 3000psi (M3K/EFG3K) and working up the pressure rating to the warmer colours, purple (M4K/EFG4K), red (M5K/EFG5K), orange (M6K/EFG6K) and yellow for 8000psi (G8K).

The consistent MegaSys® Hose Layline Hierarchy and colour system makes for easy identification, plus a minor feature/benefit is the layline repeats approximately every 61cms. In a pinch, this will give the user a method for measurement.

|

|

Hydraulic & Industrial Hose Date Codes

Date codes are used to identify at which Gates plant the product was manufactured and to determine when the product was produced.

Below is an example of how to read Gates hose date codes.

Date code: AA MMDDYY

Where : AA : Manufacturing Plant, i.e.,

BL = Belgium

IO = Iola, USA

AM = Mexico

GL = Galesburg, USA

MM: Month

DD: Day

YY: Year

Example:

IO – Produced in Iola 091307 – 13th September 2007

Hose Shelf Life

Please note: Storage environment, along with rubber materials can vary the shelf life limit. Shelf life is difficult to quantify as many variables affect the hose. Proper storage precautions can result in three to five years shelf life. Beyond this time there can be a significant service life decrease, depending on storage environment variables.

Gates recommends hose in extended storage be visually inspected and tested prior to use. Hose judged marginal should be replaced to avoid potential failure, property damage or bodily injury. Store hose on a first-in/first-out basis. Unusually long storage, or poor storage environment can deteriorate hose, reduce performance and may lead to premature failure.

Should additional information be required, please contact Gates Customer Service on +61 3 9797 9688.