There is a growing number of timing belt and component failures on popular engines. More specifically, the nature of the failure indicates an exposure of the tensioner unit and idlers to extreme heat. In some cases, the heat is so severe that it has melted the top cover of the timing belt. This extreme heat results in the failure of the automatic tensioner, influences the timing belt to ‘jump teeth’, and ultimately causes serious engine damage. Gates® Australia has seen cases where the heat generated has been so severe that the bearings have disintegrated with the vehicle having travelled less the 50 kilometers.

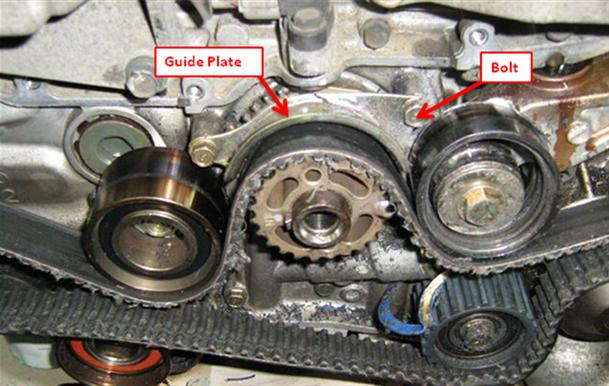

This diagram shows a typical result of the excessive heat generated from this issue:

With over 200,000 vehicles on road across Australia and New Zealand, it is very important that all automotive technicians are aware of this issue, and are armed with the correct protocols to ensure they can avoid any unnecessary complications.

Why is this problem occurring?

A large number of models (particularly with manual transmission) are fitted with a timing belt guide plate which is located directly above the crank shaft pulley. The purpose of the guide plate is to prevent belt ‘tooth jump’, and as such, is positioned very close to the timing belt.

Having said this, upon installation, the rotation of the bolts which secure the guide plate to the engine naturally forces the guide plate down towards the belt. If the guide plate is installed too close to the belt or if the bolts on the guide plate aren't tightened correctly, the plate can make contact with the timing belt cover (see diagram below). Any contact between the guide plate and belt, and/or an incorrect clearance between the timing belt and guide plate, will cause friction and generate excessive heat. This extreme heat will compromise the bearing’s lubricant and lead to bearing seizure/failure.

How to avoid the problem:

Unless special care is taken to ensure that the correct clearance is achieved between the timing belt and guide plate, this failure mode will occur. In addition to this, the correct clearance needs to be achieved consistently across the FULL arc of the guide plate.

Given the complexity and the limited space in the engine bay of this vehicle, it is extremely difficult to achieve the correct clearance through visual inspection (unless the engine is removed from the vehicle). As such, Gates® has created an innovative, new and specifically designed gauge to help automotive technicians achieve the correct clearances required. This gauge is called ‘The Gates® Timing Belt Spacer Tool’.

The Gates® Spacer Tool is Australian Design Registered with a Patent Pending, and is specifically designed to assist the automotive technician achieve correct and even clearance between the timing belt and guide plate in the affected applications. Further, the tool is accurate, safe and easy to remove upon completion of the job.

Best yet, the Gates® Spacer Tool is provided with the Gates® Timing Component Kits that suit the affected engines. So, all you need to do is look up and order the correct part number for the vehicle.

See the list of affected applications here.