|

PERFECT BELTS FOR IMPERFECT CONDITIONS

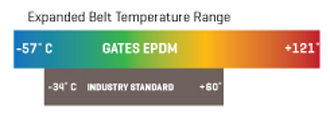

Over time, belts fail from heat cracks, stretching or excessive wear. Belt re-tensioning and replacement leads to downtime, inefficiency and loss of productivity. Only Gates® molded notch V-belts offer a patented, new ethylene construction to keep you running when others fail.

|

|