Maintenance and Energy Saving Products

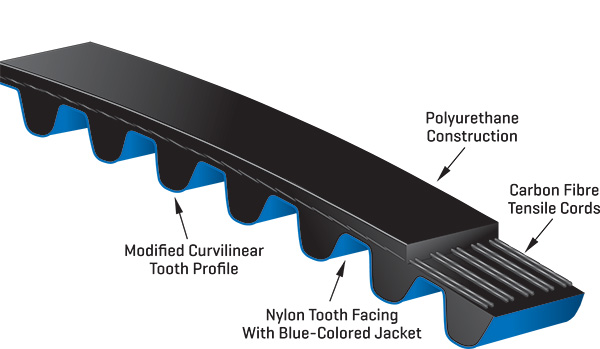

Poly Chain® GT™ Carbon™ Belts

Trying to reduce your energy bill? Experiencing downtime to re-tension and lubricate your roller chain? High moisture, oil or chemicals causing you problems?

Poly Chain® GT™ Carbon™ synchronous belts are the solution.

|

- 400% greater capacity than HTD belts

- 5% energy savings over V-belts

- 99% efficiency for life of the drive

- Cut maintenance & downtime

- Reduce weight and overhung loads

- Over 120,000 possible drive combinations

- Inert to most acids, chemicals and water

|

|

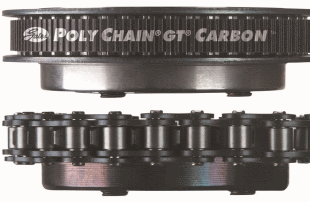

- Width-for-width roller chain conversions

- No stretch

- No lubrication

- No re-tensioning

- Outlasts roller chain up to 4 to 1

- Outlasts roller chain sprockets 10 to 1

- Inside & backside idlers can be used

Poly Chain® GT™ Sprocket Range |

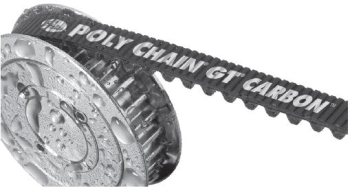

Unlike rubber synchronous belts the unique construction of Poly Chain® GT™ Carbon™ belts allow them to easily cope with wet or washdown applications and environments. Stainless steel sprockets and bushings together with Poly Chain® GT™Carbon™ belts are the ideal wet drive solution.

Stainless Steel Sprockets & Bushes

|

|

OUR GUARANTEE

If, for any reason, the Poly Chain® GT™ Carbon™ belt drive system does not meet your expectations during the first 90 days, just return all components to your Gates distributor for a full refund *

* To qualify for the 90 day risk free guarantee, the belt drive system must use a new Poly Chain® GT™ Carbon™ belt, Poly Chain® GT™ sprockets and bushings. The drive must be designed using Gates design software and installed in partnership with Gates.

|

|

PROVEN SUCCESS STORIES

Gates engineers can help develop the best drive solution for your particular application and need.

A collection of successful case studies utilising Poly Chain® GT™ Carbon™ can be found on our case studies page.

|

To find out how we can help you improve efficiency and reduce maintenance costs contact us HERE.