End Market Industry

Ore Processing - Mining

Application

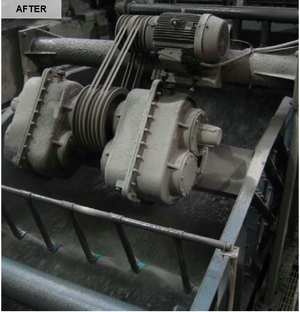

VS2 Vibrating Screen – Iron Ore

30kW @ 1485rpm

Original Components

Belts = 4 x SPC3000 Optibelt SK

DriveR Pulleys = 4/SPC300 Deep groove

DriveN Pulleys = 4/SPC450 Deep groove

ADTR-014

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

Extremely abrasive iron dust and mud would enter this V-belt drive and aggressively erode the sidewalls of both the belts and the pulleys. Rapid stretch of the standard belts would amplify this premature wear and degradation. Belts would only last between 3-4 months, requiring this critical drive to come off line for a belt change. As the ball mills feed directly onto VS1&2, this would cut production of the site in half whenever this occurred.

Solution Description

Belt = 4 x SPC3000P Predator® V-belts

DriveR Pulley = 4/SPC300 Deep groove

DriveN Pulley = 4/SPC450 Deep groove

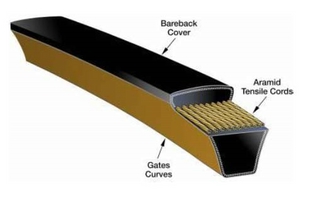

Benefits of Gates Product

Gates Predator® belts were installed and due to the sidewall protection and Aramid tensile cords are still running 12 months later. VS1&2 are now specified to run Gates Predator® only. This site has reported $25,000 savings in the first year due to increased uptime and hence higher yields.

Submitted by: Gene Halden

|