Breadth of Portfolio

Creating system solutions that address today’s industrial challenges, including Synchronous Belts, Thermoplastic Polyurethane (TPU), V-Belts, and metals.

Gates Innovation

Power transmission solutions delivering improved safety, reliability and productivity through advanced research and development.

Coverage and Support

Gates infrastructure supports customers every step of the way, through extensive distribution networks, technical application engineers, and technical sales support.

UNCHAIN YOUR OPERATIONS

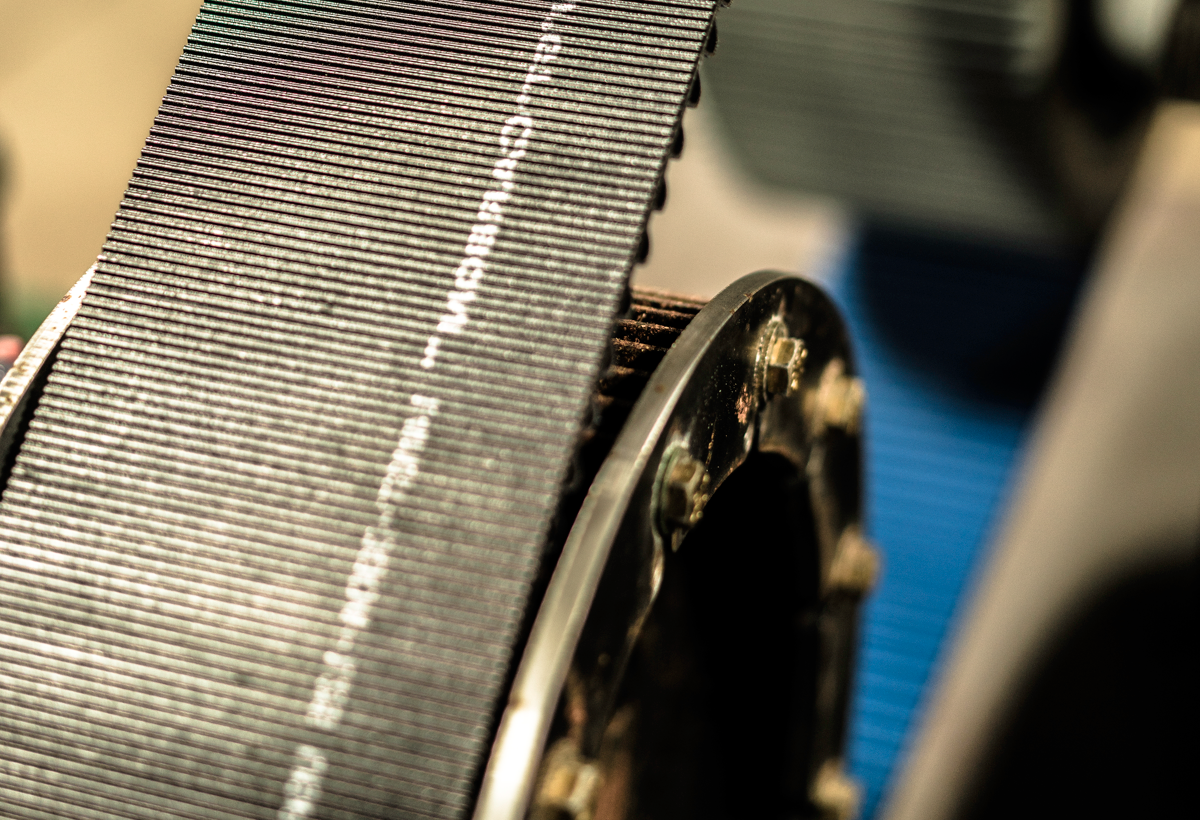

Explore Poly Chain

Get a close-up view of the benefits of Gates® Poly Chain® belts and the advanced materials science and process engineering that go into making them.

Play videoExplore Poly Chain

Get a close-up view of the benefits of Gates Poly Chain belts and the advanced materials science and process engineering that go into making them.

Play videoAdvancing

How Industry Moves

Customer Stories

Gates applies new materials, fresh perspectives, and innovative techniques to discover superior solutions for our customers’ challenges.

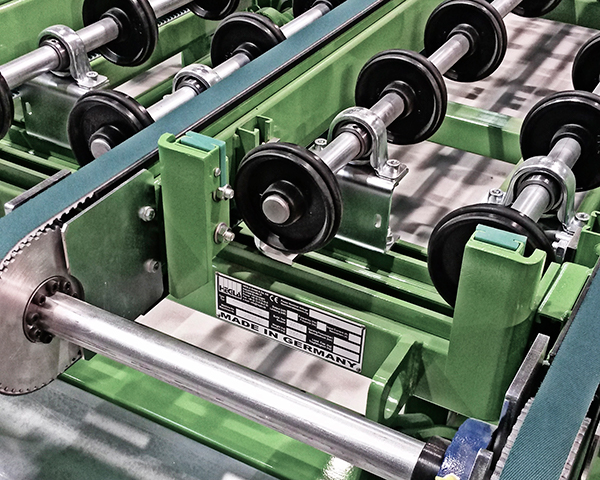

Culp Lumber

Find out how replacing roller chain with Gates® Poly Chain® belts improved uptime, productivity, and safety at this North Carolina timber mill.

Play videoContinental Paving

Learn how this New Hampshire-based asphalt company eliminated the headaches and downtime of roller chain by converting to Gates® Poly Chain® belts.

Play videoSuzhou SLAC

See how Gates® Poly Chain® belts advance product innovation at this leading manufacturer of precision equipment for the beverage industry.

Play videoBelt-Driven Since Day One

Gates Belts are not only for industrial applications. Founded in 2009, Schindelhauer was the first bike company in the world to completely forego chains and sell only belt drive bikes — a historic innovation in the bike market. Watch the video below to learn the history of our close partnership with Schindelhauer and their pioneering role in helping to introduce Gates Carbon Drive belts to modern cyclists.

Play videoUpgrade to the Modern Standard

| Traditional Methods | Gates Solutions | Benefits |

|---|---|---|

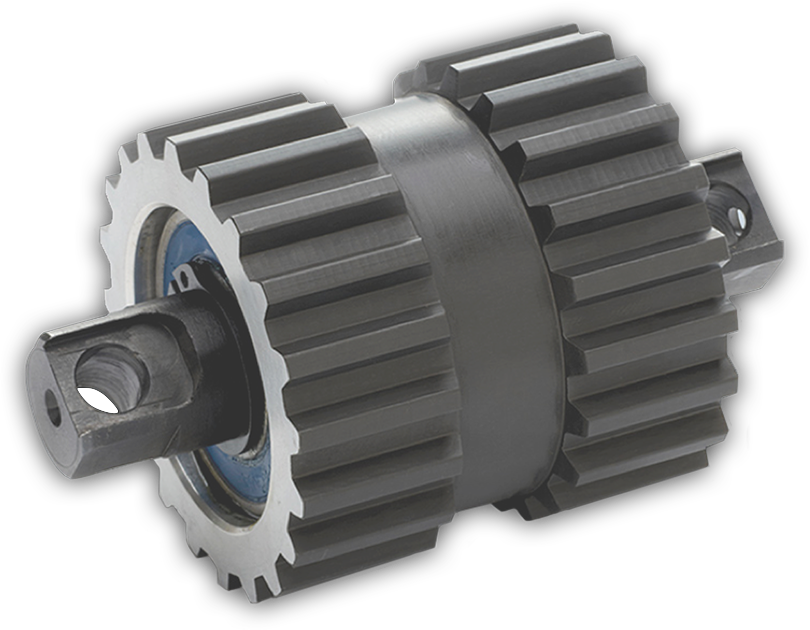

| Roller Chain | Poly Chain® GT™ Carbon™ |

|

| Gear Boxes/Direct Drive | Poly Chain® GT™ Carbon™ |

|

| Engineered Chain | Profile Thermoplastic Polyurethane (TPU) |

|

| Plastic Modular Chain | Supported Thermoplastic Polyurethane (TPU) |

|

| Lift Cables | Flat Belt Thermoplastic Polyurethane (TPU) |

|

| Lead/Ball Screw Systems | Linear Belt Thermoplastic Polyurethane (TPU) |

|

Gates Belt-Drive

Solution Portfolio

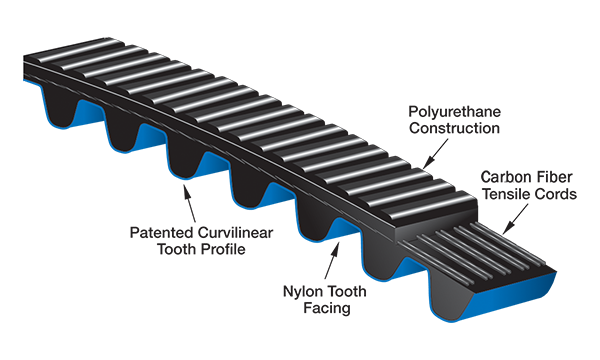

Gates® Poly Chain®

benefits versus roller chain:

- 3x longer life

- Requires no lubrication

- Virtually maintenance free, with no re-tensioning required

- Significantly reduced weight and noise

- Carbon tensile cord does not stretch

- Belt sprockets good for 2 to 3 belt changes

- Increased uptime

- No crane rental to replace the belt

- Increased safety

- Can reach virtually any center distance

Benefits of upgrade deliver payback periods as short as 6-12 months

| Lengths Available | Up to 20m (65.6ft) (pitch dependant) |

| Pitches Available | 5mm, 8mm, 14mm, 19mm |

| Widths Available | 9mm to 300mm |

| Temperature Range | -54C (-65F) to 85C (+185F) |

| Construction | Carbon Tensile Cords; Truly Endless |

| Other Features | High-Modulus cord which allows use of backside idler |

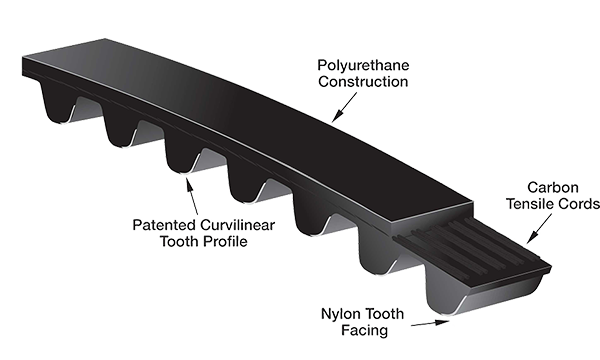

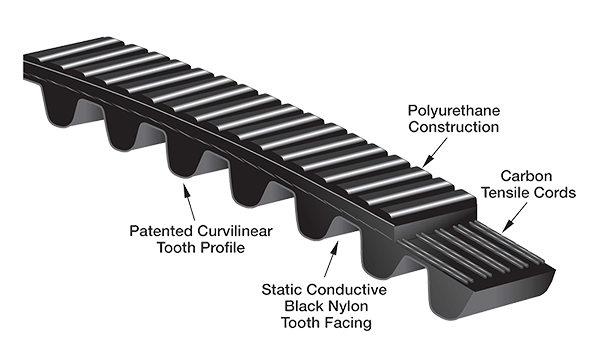

Poly Chain® GT™ Carbon™

Poly Chain® GT™ Carbon™ is the profitable solution to replace roller chain, gears and large V-belt drives. Our industry-leading power transmission technology drives savings day after day.

Poly Chain® GT™ Carbon™ Extended Length

Gates’ innovative carbon tensile technology and extended length manufacturing technology enables application of Poly Chain on larger and longer drives than ever before.

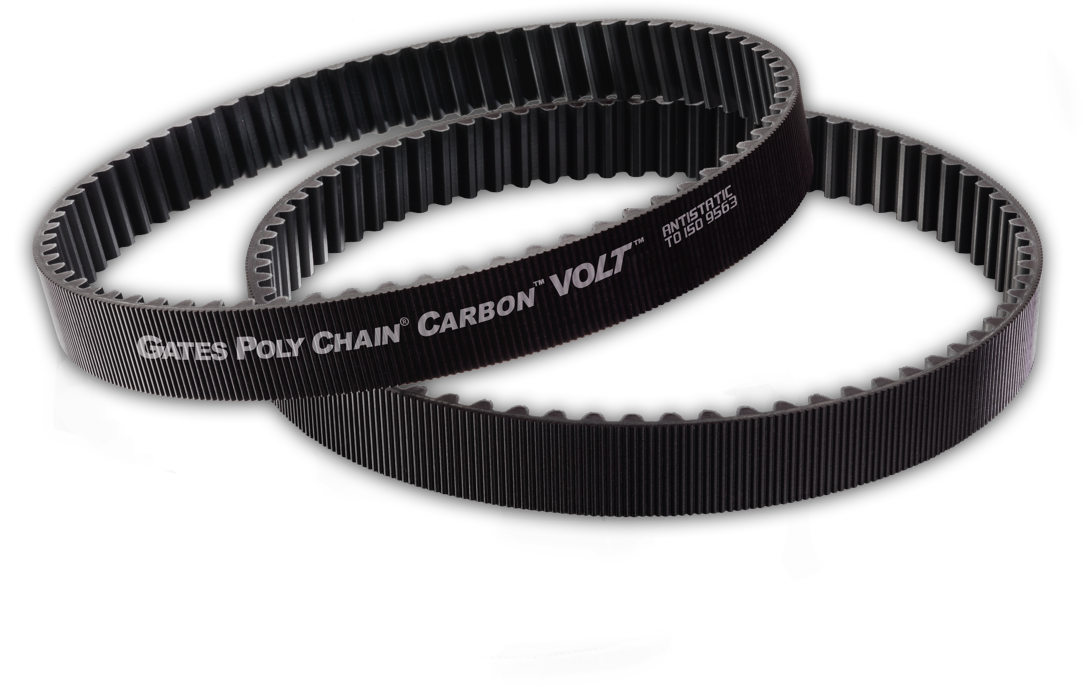

Poly Chain® Carbon™ Volt™

Suitable for high torque, low-speed drives and environments with explosive atmospheres, Poly Chain® Carbon™ Volt™ is Static conductive to ISO 9563 at time of manufacture and longer than any other belt on the market. The power you want, now with the safety you never had.

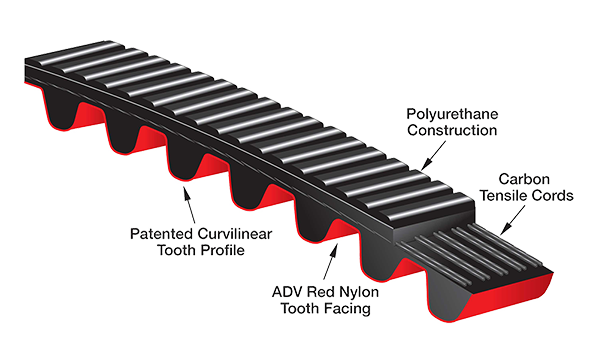

Poly Chain® ADV™

Higher power than you’ve reached before. Narrower drives than ever before. Poly Chain® ADV™ is designed for significantly reduced weight and maintenance in your high-torque applications with limited space constraints.

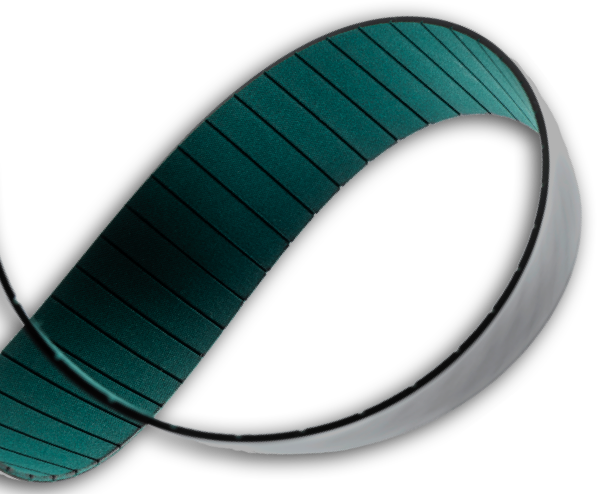

Thermoplastic

Polyurethane

Why TPU?

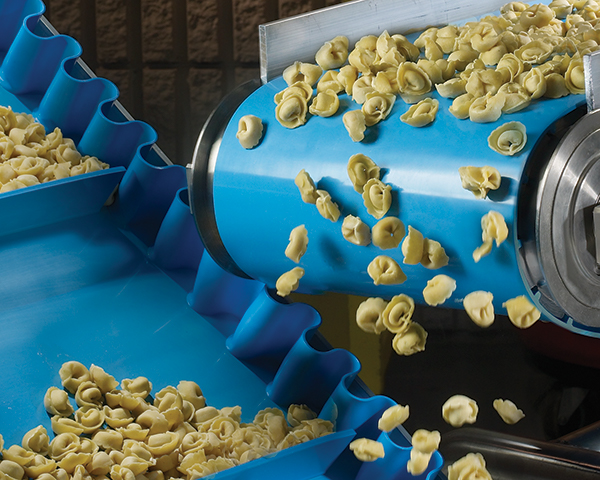

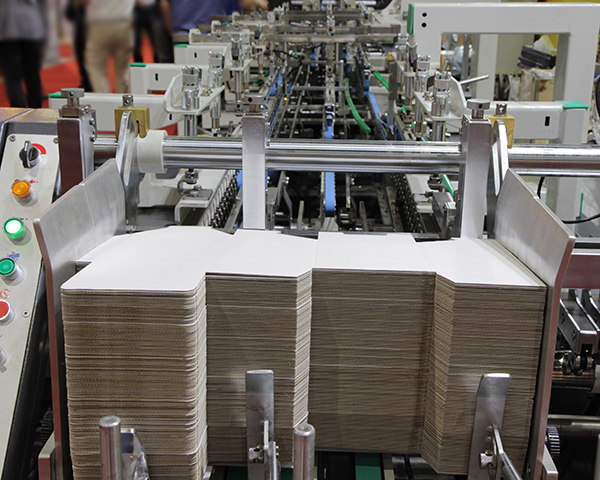

Polyurethane is extremely wear and fatigue resistant and at the same time highly flexible. TPU is abrasion- and chemical-resistant. TPU belts replace engineered chain, plastic modular chain, steel cable, ball screw systems, and more. In all of these applications, TPU offers clean and quiet performance, easier cleaning, incredible strength, and absolute precision. And, like all Gates belt solutions, no lubrication is ever required.

| Attribute | Construction | Offering | Applications |

|---|---|---|---|

| Linear Belts | Open Ended & Welded | Various Pitch, Cord Type, Resins and Coatings Available | Linear Actuation, Lifting. Material Handling, Conveying |

| Wide Belts | Welded | Various Pitches, Kevlar Cord, Widths up to 450mm | Process Conveying, Hygiene, Tire |

| Flat Belts | Open Ended | Kevlar or Steel Cord in Most | Material Lifts, Live Roller Drives, General Conveying |

| Flex Belts | Truly Endless | Various Pitch, Steel Cord, 1.5-22.5m Lengths | Up to 20m (65.6ft) Endless (Pitch Dependent) |

| Sleeves | Truly Endless | Various Pitch. Steel Cord, .12 -2.25m | Light Power Transmission, High Performance Conveying (Short Lengths) |

| Food Belts | Welded | PosiClean®, CenterClean™, FlatClean™, Kevlar Cord, Various Fabrication. Joining Options | Food Handling and Conveying |

Customised Machining

Customised Backings

Customised Profiles

Machineworks: Custom Metals

Gates Drive experts get you up and running in no time. Any design, any material, and no minimums.

Engineering

- 3x Longer Life

- Requires No Lubrication

- Packaging Design

Management

- Production Sourcing

- Field Sales Support

- Distribution and Transportation

OEM Logistics

- EAU (Estimated Annual Usage)

- Inventory Management

- Just-In-Time Delivery

- Packaging and Container

- Distribution and Transportation

The Strength of Innovation

See how Gates combines advanced material science and process engineering in pursuit of superior solutions for our customers.

Play videoBelt Selection Matrix

| Attribute | Poly Chain® | PowerGrip® GT™ | TPU |

|---|---|---|---|

| Torque | High to Low | Medium to Low | Low (Positioning) |

| Rim Speed with Standard Sprockets* | Max 6500FPM | Max 6500FPM | Max 3000FPM |

| Noise | Higher at high speeds | Medium at high speeds | Medium at high speeds |

| Length (Endless) | Up to 20m (65.6ft) (pitch dependent) | Up to 6.9m (22.5ft) (pitch dependent) | Up to 23.5m (77ft) (endless) |

| Length (Long Length) | Up to 274m (900ft) (pitch and width dependent) | Up to 180m (590ft) (pitch and width dependent) | Up to 300m (984ft) (pitch and width dependent) |

| Conductivity | Volt only | Yes (8 and 14mm) | Standard No, Special Resin Available |

| Temperature | -54°C TO +85°C (-65°F to +185°F) | -34°C TO +85°C (-30°F to +185°F) | -5°C TO +70°C (-23°F to +158°F) |

| Chemical Resistance | High | Medium | High |

| Food Applications | Yes (Not FDA) | No | Yes (FDA) |

| Customisation | Very Low | Low (some backings) | High (Backings, Profiles, Modifications) |

| Dual Sided | No | Yes (Twin Power GT2) | No |

Free Drive Design

Schedule a no-cost drive design to find out the benefits that converting chain-drive equipment to Gates belt-drive solutions can give your business. Includes complete drive design report, and detailed quote with ROI projections. Enter your information to get started.