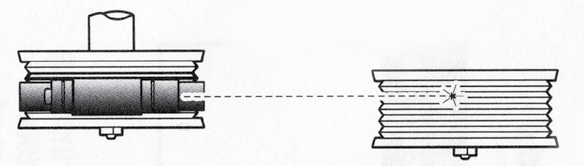

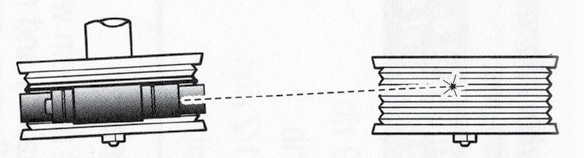

Designed to detect misalignment in serpentine drive systems, the two-piece kit contains a laser tool and a target piece, both of which are anodised red for high visibility in dark engine compartments. The laser beam itself is a large vertical line, and when coupled with the precisely etched groove in the target piece, can be used to easily identify misaligned pulleys and components. The tool works on automotive serpentine belt drives with 4 ribs or more.

Features:

Features:

-

Laser type: 650nm visible laser diode

-

Operating time: 20 hours of continuous service

-

Battery type: replaceable lithium battery

-

Specially designed magnetic feet to sit perfectly in K-section Micro-V® pulleys

-

Neatly packaged in a blow-moulded plastic case for durability during handling and storage

Did you know one degree of misalignment can raise temperatures by 16°C, reducing belt life by up to 50%?

What is misalignment?

There are two types of misalignment:

1) Offset/Parallel

2) Angular

Offset/Parallel Misalignment

Refers to pulleys that are outside the plane of other pulleys in the drive system, but whose shafts remain parallel with other components.

Angular Misalignment

Refers to pulleys which are within the drive system plane, but are tilted because their shafts are not parallel.

Pulley misalignment can cause problems, including:

- Premature wear and shorter belt life

- Belt tracking problems

- Belt stability problems

- Belt breakage

- Excess heat

- Chirping

Gates employees pride themselves on identifying and meeting customer needs and providing timely and expert advice and solutions. Contact us HERE if you require any assistance in selecting the correct products for your application or for expert advice.

Part No. 91075