End Market Industry

Roll Form Machine

Application

Manufacture of steel frames

Various high torque, low speed requirements varying per machine

APC-019

See more at www.GatesAustralia.com.au/CaseStudies

|

New Drive Design

Roll forming requires accurate positioning and involves high shock loads due to stop/start applications requiring pressing and punching of holes. Roller chain is typically used in these applications which requires ongoing lubrication to maintain accuracy otherwise accelerated wear occurs.

Solution Description

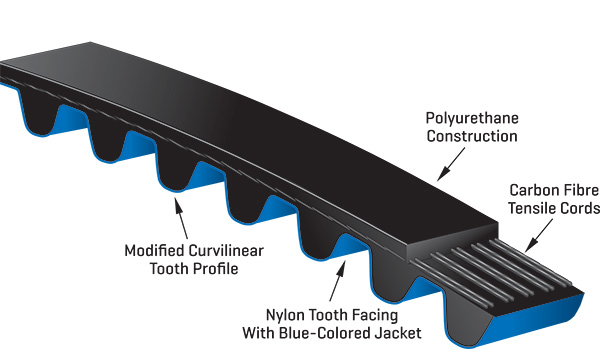

37mm wide 14MGT Poly Chain® GT™ Carbon™ belt drives

Benefits of Gates Product

An OE company saw the benefits of Poly Chain® GT™ Carbon™ as an opportunity to produce an improved roll forming machine. Utilising Poly Chain® GT® Carbon™ belts these new machines require no ongoing maintenance or lubrication.

Machines run more smoothly due to the high positional accuracy of Poly Chain® GT™ Carbon™ and accuracy is maintained.

The machines also run at lower noise levels due to accurate meshing of belts providing yet another advantage in the market for this OE. Sprocket wear is approx. 10 times less than roller chain sprockets as there is no metal-on-metal contact.

Submitted by: Neil Thomson

|