End Market Industry

Bottling

Application

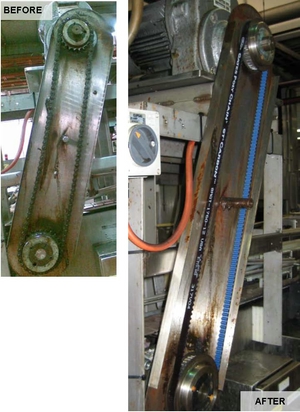

Canning line roller chain drives on conveyors

1.1kW @ 300rpm

Original Components

Chain = 5/8” simplex roller chain

DriveR Sprocket = 17 Tooth

DriveN Sprocket = 21 Tooth

APC-002

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

The largest Australian bottler was having roller chain conveyor drive issues, frequent maintenance and lubrication caused excessive downtime. High noise levels of roller chain, 55dBA on each drive. Single chain drives were changed out approx 2-3 times per year. In wash down areas roller chain would lose lubrication and rust solid.

Solution Description

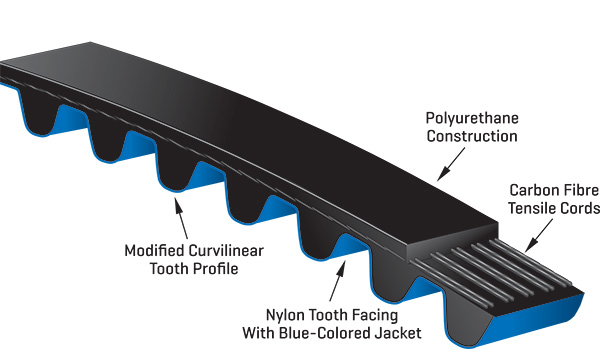

Belt = 8MGT-1760-12 Poly Chain® GT™ Carbon™

DriveR Sprocket = 40 tooth (Stainless Steel)

DriveN Sprocket = 48 tooth (Stainless Steel)

Benefits of Gates Product

After over 24 months of running the Poly Chain® GT™ Carbon™ drives show no signs of wear on either the belts or sprockets. The entire bottling site has now been converted to Poly Chain® GT™ Carbon™ drives. The drives are very clean with no grease, lube or maintenance required.

Noise levels have dropped to 40dBA on each drive. Drives have remained untouched since the installation.

Submitted by: Gene Halden

|