End Market Industry

Quarry Industry

Application

Canica Cone Crusher

185kW @ 1480rpm

Original Components

Belts = 5 x 8V2120 V-belts

DriveR Pulley = 5/8V15.3 (389mm Diam.)

DriveN Pulley = 5/8V22.4 (569mm Diam.)

ADTR-013

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

A VSI cone crusher drive required pulley replacement. The cost of replacing the standard 8V pulleys meant importing from the USA or machining them in Australia from a billet of steel, both options being extremely expensive.

Solution Description

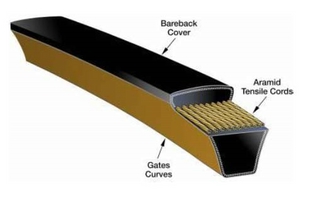

Belt = 4 x SPC5300P Predator® V-belts

DriveR Pulley = 4/SPC380

DriveN Pulley = 4/SPC560

Benefits of Gates Product

By utilising Gates Predator® belts, we were able to redesign this drive using the more common SPC belt cross section. This meant standard, off the shelf SPC pulleys could be sourced locally and SPC Predator® belts were installed, providing a more cost effective solution. Even though the new drive uses fewer belts, the power capacity of the Kevlar corded Predator® belt means the full 185kW is easily delivered.

Submitted by: Gene Halden

|