End Market Industry

Paper Mill

Application

Re-chipper

110kW @ 1485rpm

Original Components

Belts = 10 x SPB3750 Challenge V-belts

DriveR Pulley = 10/SPB280

DriveN Pulley = 10/SPB650

ADTR-012

See more at www.GatesAustralia.com.au/CaseStudies

|

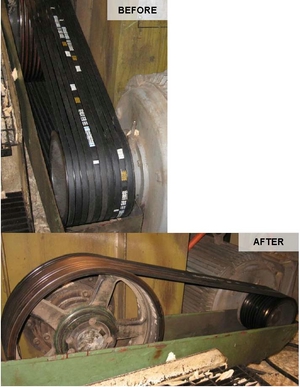

Problem

The existing belts were stretching, slipping and only lasting 2 months. A blockage in the chipper had caused the belts to slip severely and ignited sawdust beneath the drive starting a fire.

Downtime costs are $30,000 per hour.

Solution Description

Belt = 10 x SPC3750P Predator® V-belts

DriveR Pulley = 10/SPB280

DriveN Pulleys = 10/SPB650

Benefits of Gates Product

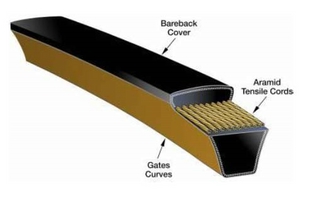

Predator® belts were installed and lasted 12 months without any maintenance or retension required. The bare back cover of the Predator® belts allow them to slip during blockages without burning or damaging the belts.

With belt changes taking approximately 2 hours per set, the potential downtime costs saved is $300,000 per year.

Submitted by: Gene Halden

|