End Market Industry

Paper Mill

Application

Primary pressure screen

250kW @ 1489rpm

Original Components

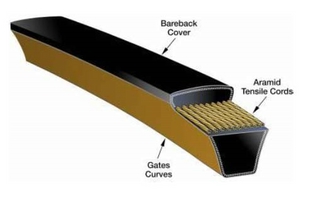

Belts = 8 x SPC5600 Challenge V-belts

DriveR Pulley = 8/SPC315

DriveN Pulley = 8/SPC1250

ADTR-011

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

The existing V-belts would stretch, slip and fall off the vertical drive shaft, halting production until they were replaced.

Downtime costs are $30,000 per hour.

Solution Description

Belt = 8 x SPC5600P Predator® V-belts

DriveR Pulley = 8/SPC315

DriveN Pulley = 8/SPC1250

Benefits of Gates Product

Predator® belts have been installed and after 12 months no maintenance or retensioning has been required.

With belt changes taking approximately 2 hours per set, the potential downtime saved is $660,000 per year

Submitted by: Gene Halden

|