End Market Industry

Quarry

Application

Twin drive cone crusher

185kW @ 1440rpm x 2 motors

Original Components

Belts = 12 x SPC4500 Optibelt Red Power II V-belts

DriveR Pulleys = 6/SPC375

DriveN Pulley = 12/SPC375 (made to order

ADTR-006

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

A major Australian quarry was experiencing problems with their current drive system. Existing belts were only achieving a short service life (6 months maximum), due to badly worn belts, pulleys and loose belts. The drive components required replacement.

Solution Description

Belts = 8 x SPC4500P Predator® V-belts

DriveR Pulleys = 8/SPC375

DriveN Pulley = 8/SPC375

Benefits of Gates Product

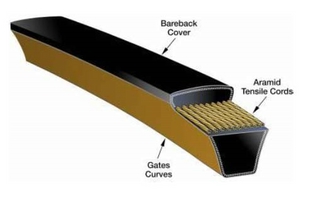

The drive has now been running for over 12 months without adjustment. The Kevlar® tensile cords inside the Predator® belts allow shock loads to be dealt with easily and tension is maintained to provide constant crushing.

Due to narrower standard pulleys and a decreased number of belts the quarry saved over $6000 on installing this new Predator® belt drive.

This doesn’t even include reduced downtime and maintenance costs.

Submitted by: Neil Thomson

|