End Market Industry

Raw Material Processing

Application

Nash vacuum pump operating on-site at an aluminium smelter

240hp @ 545rpm

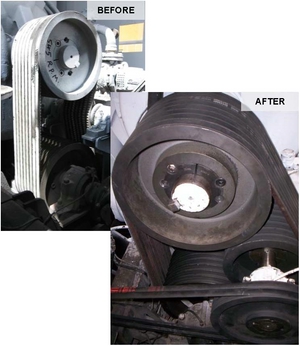

Original Components

Belts = 8 x XPC2500 Raw-edge V-belts

DriveR Pulley = 8/SPC375

DriveN Pulley = 8/SPC375

Idler = 100mm O.D. - backside

ADTR-002

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

Oxide dust in the environment was impregnating the sidewalls of the raw-edge V-belts, causing the belts to slip, heat up and crack. The vacuum pump was also subject to high shock loads, which polished and hardened the sides of the belts, inducing slip. Belt life was limited to 6 weeks.

Solution Description

Belt = 8 x SPC2500P Predator® V-belts

DriveR Pulley = 8/SPC400

DriveN Pulley = 8/SPC400

Idler = 8/SPC280 - inside

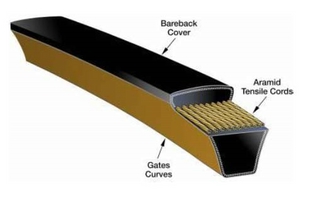

Benefits of Gates Product

Predator® belts are still running 12 months on – 9 times longer than the previous high capacity V-belts – due to the heavy-duty construction that reduces friction and heat build-up under shock loads at start up.

Submitted by: Gene Halden

|