End Market Industry

Quarry

Application

Cone crusher

150kW @ 990rpm x 2 motors

Original Components

Belts = 12 x 8V1600 V-belts

DriveR Pulleys = 6/8V570 (made to order)

DriveN Pulley = 12/8V625 (made to order)

ADTR-001

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

A large Australian quarry was experiencing problems with their current drive system. Belts and made to order pulleys were badly worn and the drive required full replacement. The existing drive required the belts to be replaced every 6 months.

Solution Description

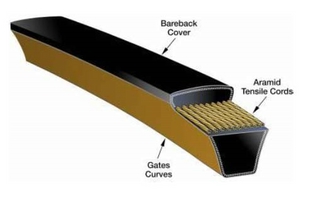

Belts = 8 x SPC4000P Predator® V-belts

DriveR Pulleys = 4/SPC530

DriveN Pulley = 8/SPC630

Benefits of Gates Product

The Predator® drive has run for over 18 months untouched. The drive now weighs less (102kg vs. 206kg) and is 40% narrower (213mm vs. 355mm). This reduction of weight and overhung load reduces wear on expensive components such as bearings and shafts. The narrower pulleys and a decreased number of belts have saved the quarry over $8000 on installation costs for this new Predator® belt drive. This doesn’t even include reduced downtime and maintenance costs.

Submitted by: Gene Halden

|