End Market Industry

Coal Mine (Bowen Basin)

Application

Rejects pump

450kW @ 980rpm

Original Components

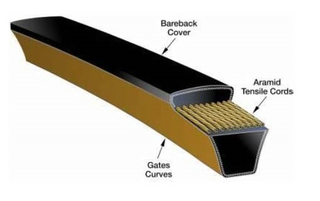

Belts = 10 x SPCX3550 Carlisle Raw-edge V-belts

DriveR Pulleys = 10/SPC530

DriveN Pulley = 10/SPC560

ADTR-021

See more at www.GatesAustralia.com.au/CaseStudies

|

Problem

The current belts were lasting 6 months on the drive with monthly retensioning. The abrasive mining environment is not suitable for these raw-edge, notched belts as they have no wrapped cover to protect them. The belts would stretch, slip and lead to increased pulley groove wear creating unscheduled downtime to regularly retension them.

Solution Description

Belts = 8 x SPC3550P Predator® V-belts

DriveR Pulleys = 10/SPC530

DriveN Pulley = 10/SPC560

Benefits of Gates Product

Only 8 Predator® belts are required to transmit this load due to their higher power capacity. The Predator® belts have achieved 14 months service without showing any abnormal signs of wear.

No maintenance or retensioning has been required on the Predator® drive.

Lower cost, 8 groove pulleys can be installed when the 10 groove pulleys require replacement. This will decrease over hung loads and weights on the shafts.

Submitted by: Neil Thomson

|