End Market Industry

Tin Mine

Application

Cone crusher

150 kW @ 1485rpm

Original Components

Belts = 6 x SPC2360 Carlisle V-belts

DriveR Pulley = 6/SPC380

DriveN Pulley = 6/SPC380

ADTR-016

See more at www.GatesAustralia.com.au/CaseStudies

|

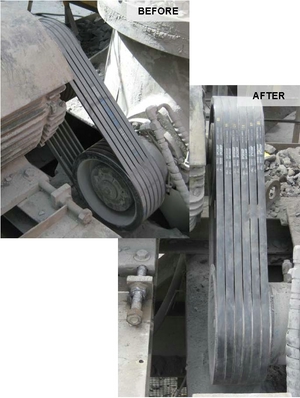

Problem

A large tin mine was experiencing extremely poor belt life on one of their cone crushers. Belts were only lasting around 6 weeks. The belts would stretch rapidly and slip, then burn off. Belt failures would require the manual removal of rocks from the crusher, enabling it to be re-started.

Solution Description

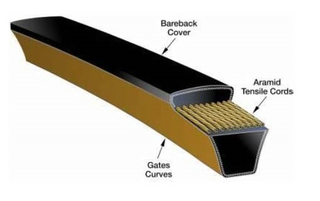

Belts = 6 x SPC2360P Predator® V-belts

DriveR Pulley = 6/SPC380

DriveN Pulley = 6/SPC380

Benefits of Gates Product

The new Predator® belts easily cope with the shock loads and power of this drive. They have not required retensioning and have been in service for 12 months since installation.

The mine has experienced large savings on new belts, installation and maintenance costs. Downtime costs have also been reduced significantly.

Submitted by: Gene Halden

|